Trellisign Mechanical Solutions

Comprehensive mechanical Solutions for Industry and Research

Comprehensive mechanical Solutions for Industry and Research

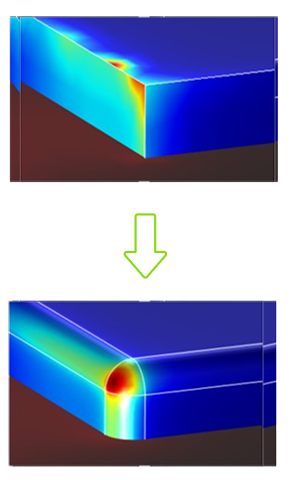

In engineering design, there is a critical need to accurately analyze and predict the response of structures to external forces, including dead loads, live loads, wind, seismic activity, temperature variations, and other environmental conditions. The challenge lies in evaluating the behavior of complex structures under various load combinations, accounting for material properties, geometry, boundary conditions, and the potential for failure modes such as buckling, fatigue, cracking, or collapse.

Structures are the foundation of modern civilization, providing the strength, stability, and safety essential for buildings, bridges, and other infrastructure. Structural engineering plays a crucial role in designing and ensuring the integrity of these structures, enabling innovation in construction and resilience in the face of natural forces. Our solutions in structural design, analysis, and optimization drive the future of safe, sustainable, and efficient infrastructures.

Integrating structural analysis tools with other systems enhances the overall workflow, improves data accuracy, and streamlines project management.

Many structural analysis tools offer APIs and Scripting tools that enable custom integrations with other software tools. Python, C#, and VBA are commonly used for scripting the integration between tools, automating workflows, and ensuring seamless data exchange. Custom scripts can automate the transfer of data (e.g., model parameters, loads, or analysis results) between software, reducing manual work and minimizing errors.

Cloud-Based Platforms facilitate collaboration in real-time by providing a shared environment for storing and updating project data ensuring everyone works with the most up-to-date information.

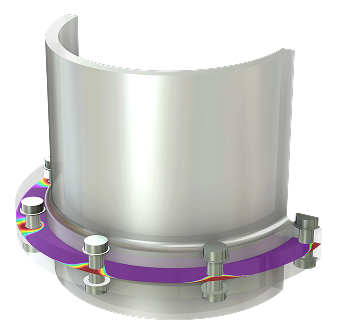

Structural integrity of the body.

Large pressure vessels, tanks, and reactors.

Composite structures and advanced alloys.

Stents and other medical devices.

Structural analysis for railway systems.

Design and analysis of marine vessels.

Structural integrity in power plants.

"Given the increasing demand for high-performance materials and systems in industries such as aerospace, automotive, electronics, and civil engineering, there is a critical need to analyze and predict the thermal behavior of components and structures under a wide range of temperature conditions. The challenge is to understand how temperature variations—due to internal and external sources such as mechanical forces, heat generation, environmental conditions, and operational processes—affect the material properties, structural integrity, and overall performance of these systems."

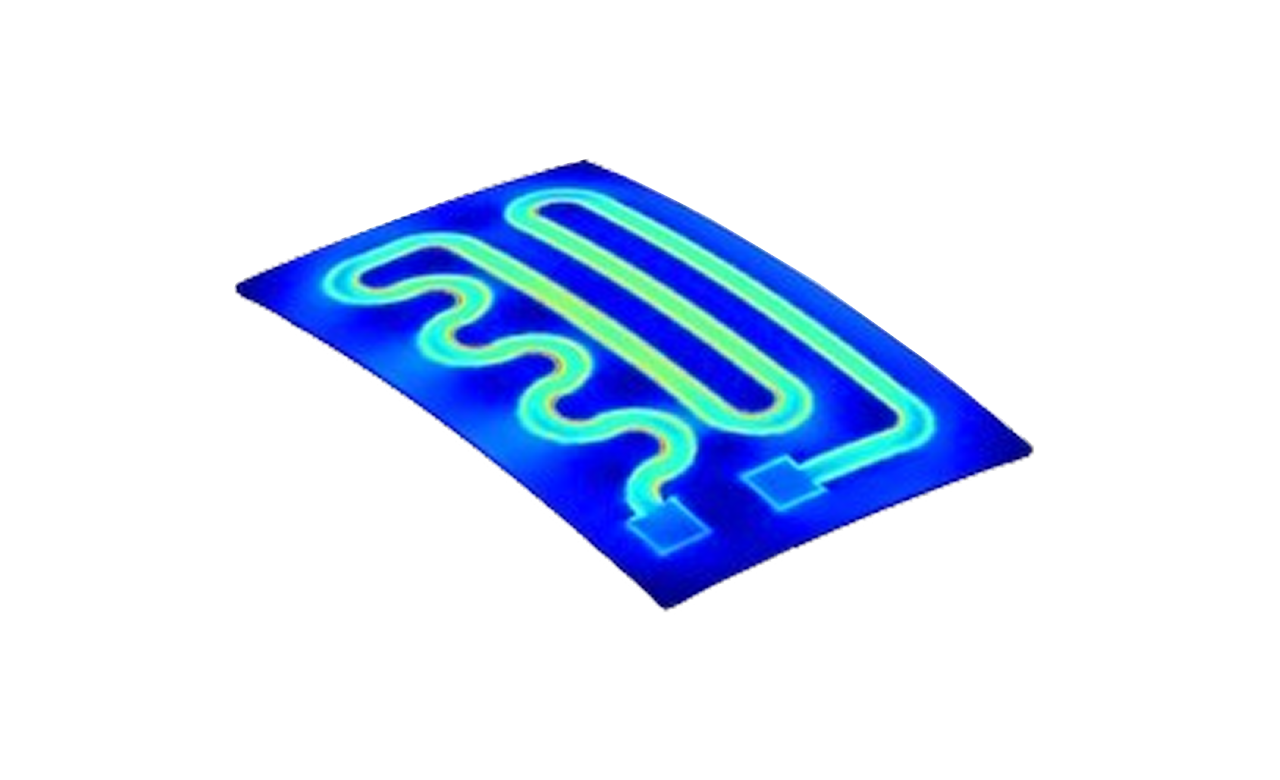

Efficient thermal management is crucial for the optimal performance and longevity of systems across industries, from electronics and automotive to energy and manufacturing. Accurately simulating and managing heat flow, thermal distribution, and temperature effects helps ensure that components operate safely and effectively in various conditions. Our advanced thermal simulation solutions empower engineers to model, analyse, and optimize thermal systems for enhanced performance, energy efficiency, and durability.

Handles steady-state and transient thermal loads, including heat conduction, convection, and radiation models.

Considers thermal conductivity, specific heat, and temperature-dependent behavior, including phase changes.

Defines fixed temperatures, heat fluxes, and temperature-dependent boundaries for accurate thermal modeling.

Supports steady-state, transient, and thermal stress analyses to study temperature effects on structures.

Ensures mesh refinement, numerical stability, and convergence checks for precise temperature predictions.

Adheres to thermal analysis codes and regulations like ISO, ASME, or ASTM for safety and performance.

Compares results with known solutions, experimental data, or analytical models for model accuracy.

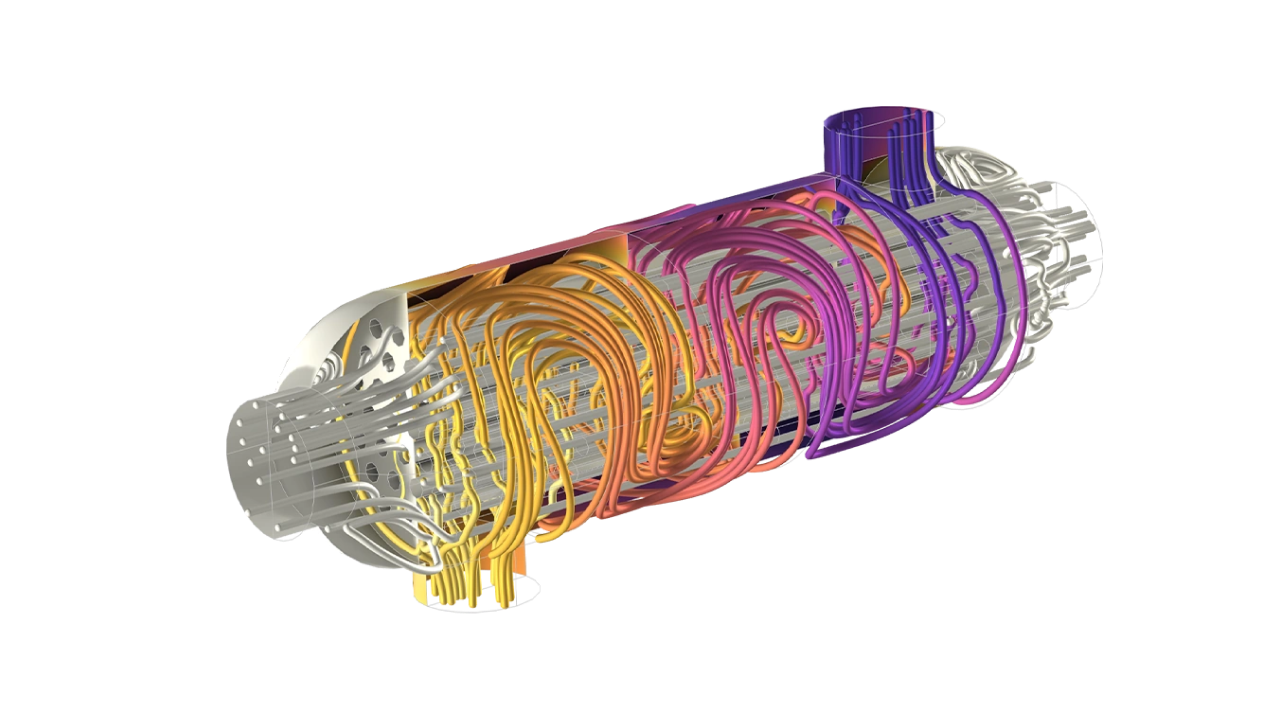

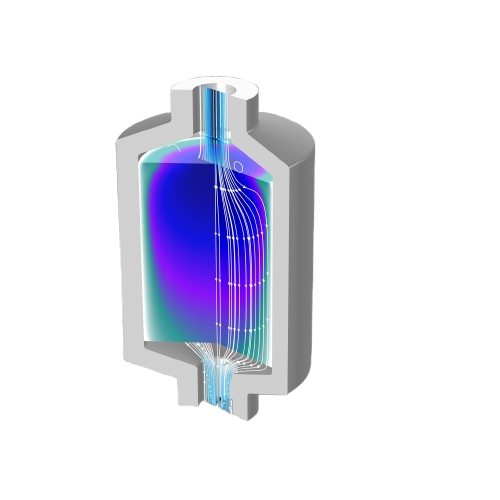

In engineering and design, the challenge is to accurately predict and optimize the behavior of fluids within complex systems—ranging from airflow over aircraft wings to heat dissipation in electronic devices and water flow in piping systems. The problem lies in understanding how fluids interact with structures, how energy is transferred between fluid layers, and how various forces (e.g., turbulence, viscosity, thermal gradients) influence the flow and system efficiency under varying operational conditions. The goal is to simulate and predict these fluid behaviors in a computationally efficient manner, ensuring that the design performs optimally while minimizing energy consumption, material use, and environmental impact.

Fluid dynamics plays a pivotal role in optimizing designs for various industries, from automotive and aerospace to energy and HVAC systems. Accurate simulation of fluid flow, heat transfer, and multi-phase interactions ensures that systems are efficient, safe, and optimized for real-world conditions. Our Computational Fluid Dynamics (CFD) solutions provide engineers with powerful tools to model and analyse fluid flow, temperature distributions, and complex thermal effects to enhance performance and reduce operational costs.

Simulates fluid flow, analyzing velocity, pressure, and turbulence.

Offers turbulence models (e.g., k-ε, LES) for complex flows.

Supports multiphase fluid simulations with surface tension and phase changes.

Models heat transfer via conduction, convection, and radiation for thermal management.

Simulates combustion processes, including chemical reactions, emissions, and flame dynamics.

Provides structured and unstructured meshes, with adaptive mesh refinement for improved accuracy in critical regions.

Simulates fluid-structure interaction, including deformable boundaries and flow-induced vibrations.

Combines fluid dynamics with heat transfer, electromagnetics, and acoustics for complex analyses.